Propeller Bead Filter Operation & Backwash

Routine backwashing of the Propeller Bead filters mitigates high waste loads.

When backwashing for clarification, wait longer between backwashes. Backwash when the pressure builds up, but does not exceed the max pressure specified by the filter. This allows for maximum solids capture.

When backwashing for biological filtration, do not spin the propeller for longer than a minute. Excessive abrasive backwashing will knock off the nitrifying bacteria that gives you even water quality. Beads should appear tan or beige and fuzzy when they have a healthy biofilm.

There are two methods of backwash operation, standard and pressurized with their procedures explained below.

Propeller Bead Operation

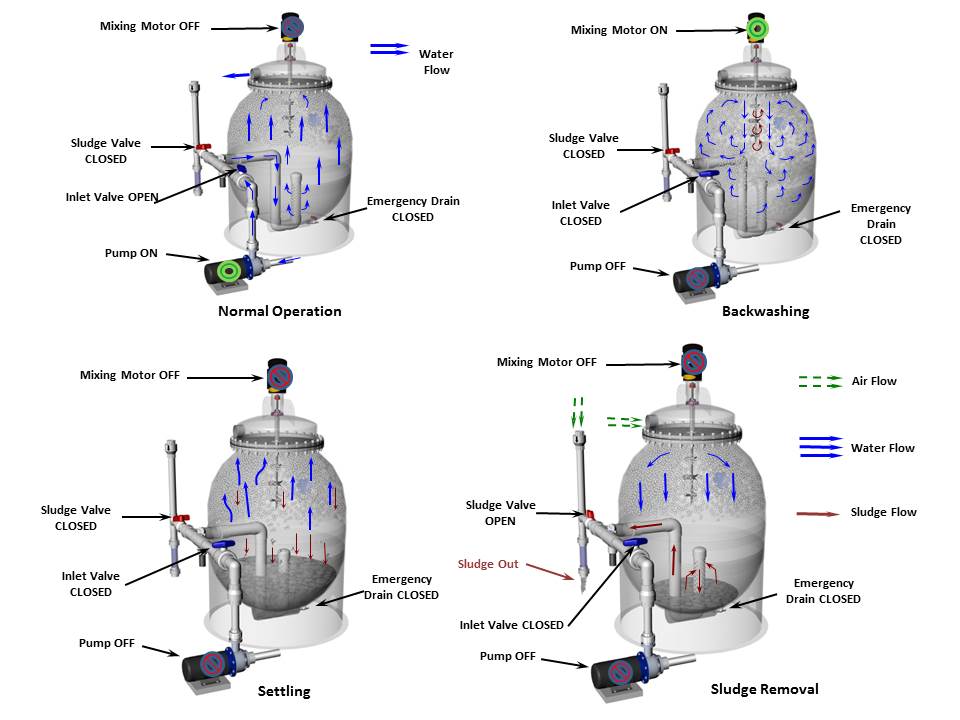

- Pump Off

- Inlet Valve Closed

- Mixing Motor on for 30-60 Seconds or until Beads Fluidize. Excessive mixing will scour beneficial bacteria off of the beads.

- Mixing Motor Off

- 10 Minute Settling Time. Allows Solids to Settle and Bead Bed to Reform.

- Open Sludge Valve and Drain Sludge until Water Runs Clear.

- Close Sludge Valve

- Open Inlet Valve

- Turn Pump On – Resume Normal Operation.

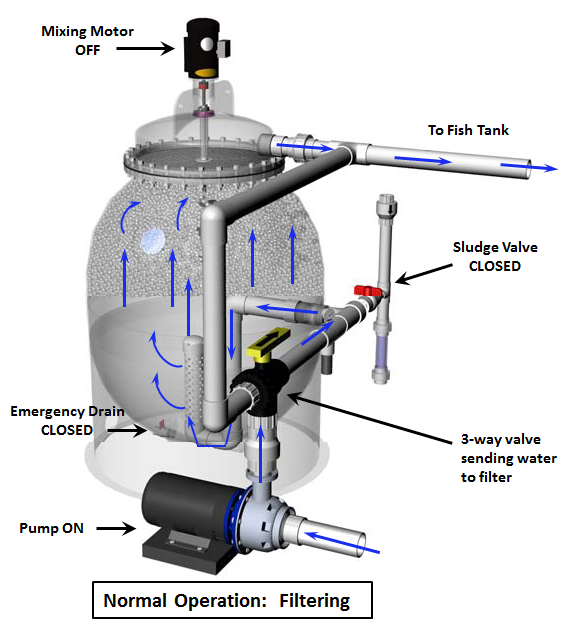

Normal Operation:

- The Pump (A) is turned on and water enters through Filter Inlet (B) and Diffuser (C).

- Water passes through Bead Bed (D) for bioclarification, then through the Bead Retention Screen (E) and finally exits through Effluent Line (F).

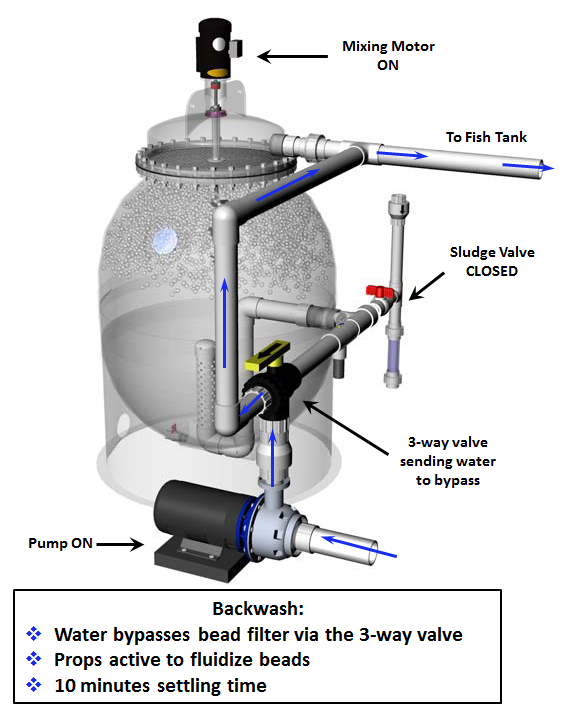

Backwash:

- The Pump (A) is turned off and the Inlet Valve (B) is closed.

- The Mixing Motor (G) is turned on. The propellers agitate the Bead Bed until fluidization occurs (15-45 sec), expanding the bead bed and separating the solids from the beads.

- The Mixing Motor is turned off and the solids are allowed to settle (for 10 min) into the Internal Settling Zone (H).

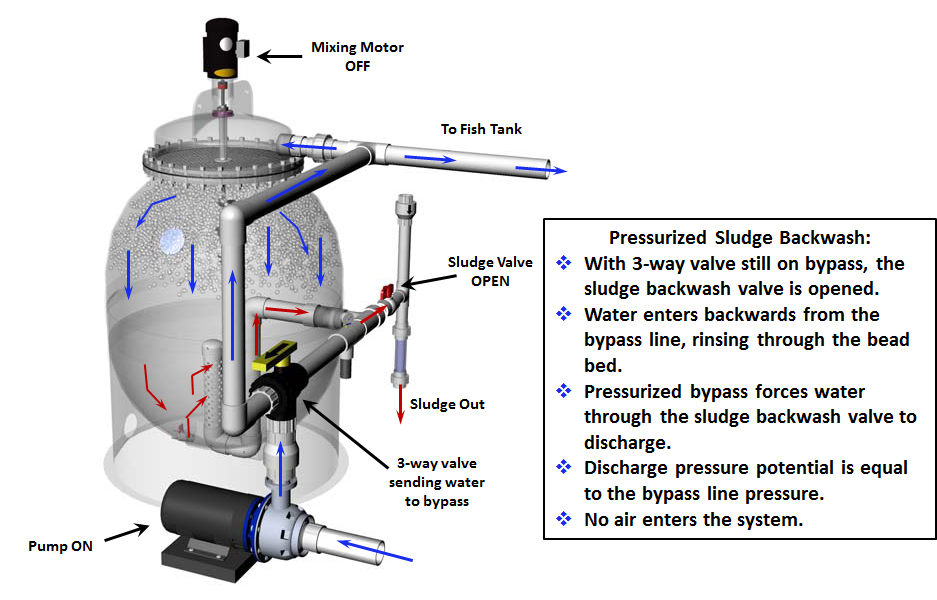

- The Sludge Valve (I) is opened and the concentrated sludge is allowed to drain from the filter via gravity. Backwash frequency is dependent on the feed rate. Water loss is typically 2-5 gpm/ft3 of bead media.

- After sludge is drained from the filter unit, the Sludge Valve (I) is closed, Inlet Valve (B) is opened and the Pump (A) is turned back on.

- An unscreened Emergency Drain (J) is provided at the bottom of the filter unit.