Filter Engineering & Design

Custom Filtration Solutions

Work Directly With Our Engineering and Design Team

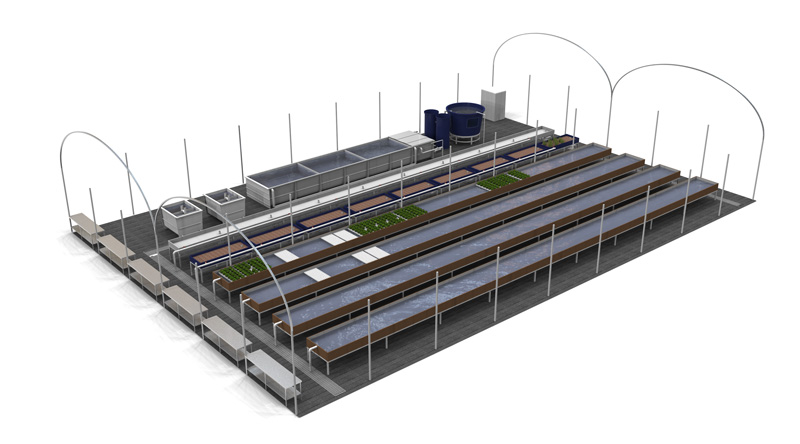

Are you planning a large facility or complex aquaculture project? Our engineering team can help conceptualize, design, and create a complete custom system that is tailored to your specific needs. From design to installation, the engineers at AST are ready to apply over 20 years of biofiltration experience to your large scale operation.

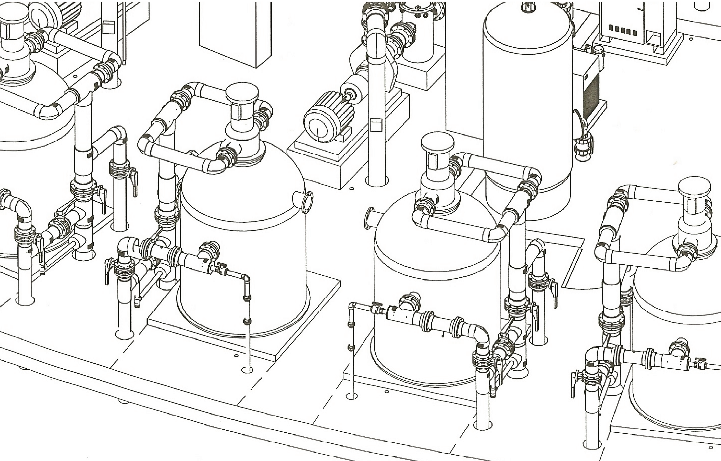

Our filters are engineered and manufactured in-house to remove solids and maximize clarification while minimizing water usage; no matter your parameters, our team can help you keep your water clean.

Each filtration application poses different engineering challenges, and no two projects are the same. This is why we have built a business around designing, building, and expertly installing customized filtration systems for a multitude of industries.

Our Phased Engineering Approach

Phase 1: Conceptual System Design

- Professional assessment of project feasibility. This includes identification of biological and physical design criteria so that the critical design decisions may be resolved. Specific criteria that will be defined include annual production goals, harvesting and stocking schedules, required water quality parameters and site criteria.

- Identification of water treatment and culture system unit processes and elements that will meet the design criteria

- Integration of the design criteria and identified design elements into a complete conceptual design for the entire facility. Conceptual design will include life support systems selection, initial facility layout, final process design and capital equipment cost estimations.

Phase 2: Detail Design and Project Management

Finalization of the biological and physical design criteria and the unit process system design and associated systems for an inclusive facility. Facility components can include office, laboratory, shop, quarantine, broodstock, fry, fingerling and grow out systems, monitoring and control systems, and effluent treatment/recycle facilities.

The following detail design tasks will be addressed:

- Finalize biological and physical design criteria- production goals and grow out schedule, harvest and

stocking schedule, biological growth parameters and site requirements. - Major equipment specification and selection—individual production systems (to include tank size,

circulation, solids capture, bio filtration, aeration/degassing, disinfection), monitoring and control

equipment, laboratory equipment. - Equipment layout and plumbing- detailed sketches of each production system showing layout,

elevations, and major plumbing requirements including a basic plumbing parts list. - Capital cost estimation- estimations of individual system component costs.

Construction management assistance during facility construction. Representatives from AST can be commissioned to attend construction meetings/ site inspections during systems installation. AST can also clarify any construction issues that arise with regard to the intent of the design.

Phase 3: Stamped Engineering Construction Drawings to be Done by an A/E Firm if Required

Call us today to find out how we can help you plan and execute your vision. 1.800.939.3659

Custom Filtration System Projects

Let's Discuss Your Project

From a simple filter to a complete custom system, our engineers can help you find the perfect filtration system for your needs. Get in touch today!