High Profile PolyGeyser Operation & Backwash

Operation Diagrams

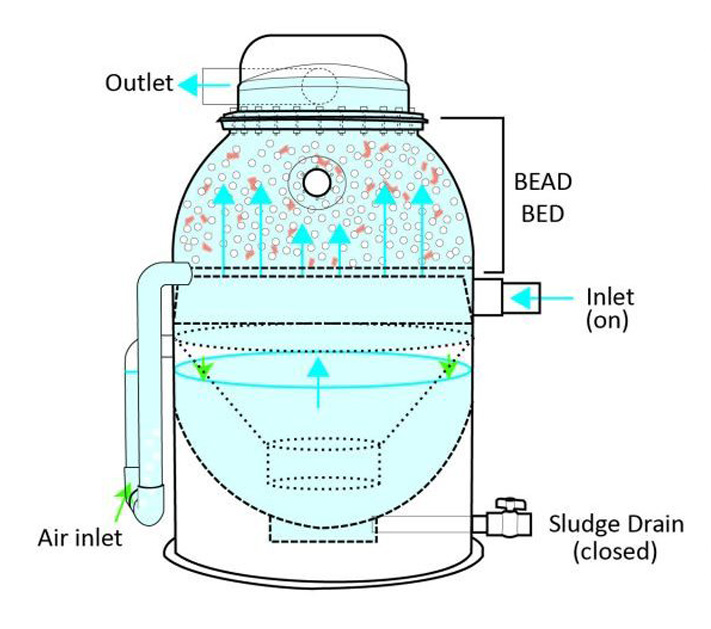

Normal Filtration

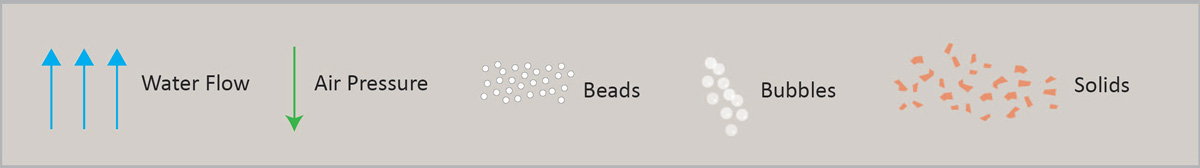

During the filtration mode, water continually enters the filter beneath the bed then passes through the bed where the solids are captured. Biofilms develop on the bead surfaces.

Meanwhile, air is slowly injected into the charge chamber. The bottom half of the HPPG filter, builds a charge for a backwash event and then functions as a settling basin, recycling the backwash water.

The increase in air pressure pushes the water downward through the charge chamber compartment then up through the center conduit of the cone. This is a very slow process; the solids swept into the charge chamber during the last backwash settle out. The clear water is then pushed back through the bead bed as it re-enters the recirculating loop.

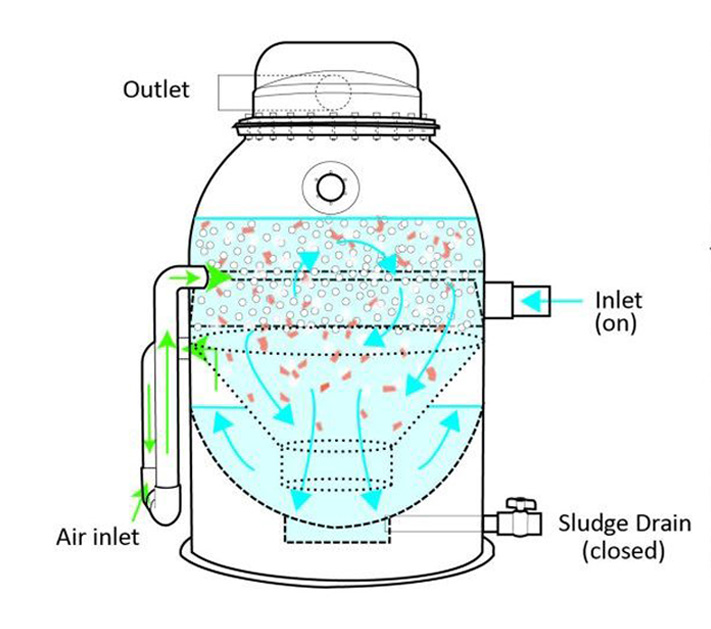

Early Backwash

No air escapes the air chamber until it is filled; then the air is suddenly released through the trigger mechanism. The bubbles exit the trigger just beneath the bead bed. The bubbles agitate the beads; knocking solids and biofilm off the beads. Water continues to flow into the unit, but no water flows out of the filter during the short three to five second backwash event.

As the beads are washed, the entire bead bed drops as the dirty water underneath is drawn into the charge chamber, replacing the air that is escaping through the trigger. Solids that settled into the sludge compartment are briefly re-suspended and aerated.

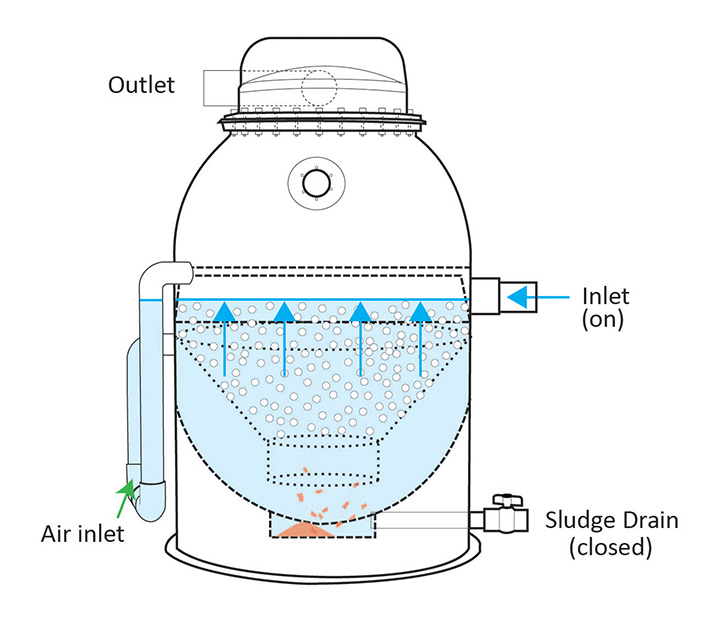

End Backwash

Eventually, the water rising in the sludge chamber floods the trigger, bringing water movement in the charge chamber and sludge basin to an end.

Solids begin to continue to settle as the filtration chamber is refilled with the water from the inlet. The beads float up to reform the bead bed. As soon as the water rises to the outlet, filtration resumes

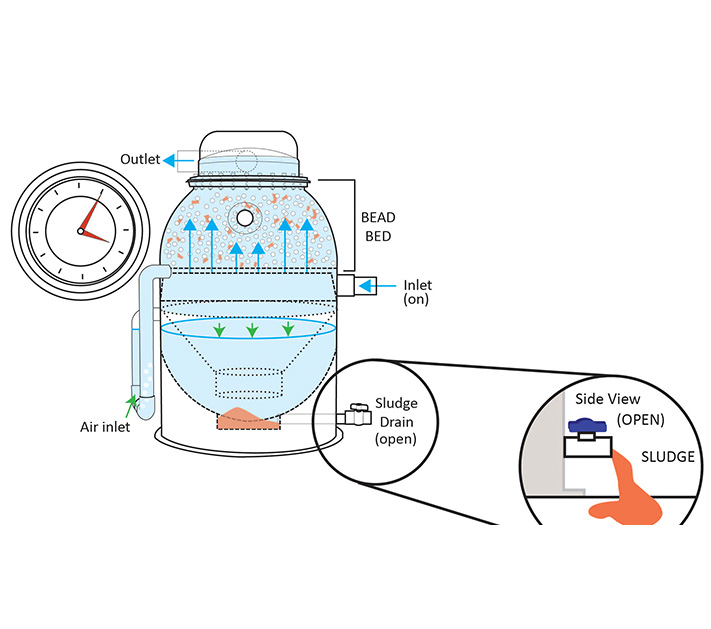

Periodically Drain Sludge

The filter will continue to filter and backwash itself several times a day. After the sludge has built up, the user can open the sludge valve to drain the concentrated sludge from the filter. A natural fertilizer, the sludge can be poured out on the lawn or nearby plant where it will naturally degrade.

Operation Overview

The PolyGeyser® Bead Filter technology stands apart from other bead filters primarily through its automatic pneumatic backwash mechanism. Water is introduced below the bed of packed EN bead media and travels upward through the filtration chamber where mechanical and biological filtration takes place. Simultaneously, air is slowly introduced into the air charge chamber at a constant, predetermined rate to achieve the desired backwash frequency. Once the charge chamber has reached capacity, the pneumatic trigger fires, releasing the entrained air from the charge chamber below the media bed. The sudden release of air from the charge chamber causes the beads to mix, roll and “drop” as the air agitates the beads.

The circulation pump/airlift operates continually, which ensures that the filter chamber begins refilling immediately after each backwash event. This causes the beads to float upward and reform as a bed. During the recharge cycle (a few hours), suspended solids in the trapped backwash waters settle into the sludge storage chamber for later disposal via the sludge drain valve (usually every 3 days- 1 week). At the same time, the clarified backwash waters are passed slowly through the bead bed again eliminating any backwash water losses.

The elimination of water loss associated with backwashing is a key element in this new technology. In most applications, dozens of backwash sequences can be automatically executed before sludge removal is required. There is no water loss associated with the backwash process and the water loss associated with sludge drainage is negligible. This strategy is particularly advantageous for marine systems, where the loss of saltwater must be minimized.

The pneumatic strategy breaks the linkage between backwash frequency and water loss and allows the nitrification capacity of the unit to be fully utilized. Frequent backwash sequences have proven advantageous for optimizing the nitrification capacity of the unit. Numerous gentle scrubbing cycles promote high rates of nitrification by maintaining a healthy thin biofilm on the bead surfaces.

Typical backwash cycles occur once every three to six hours. In recirculating bioclarifier applications, where the High Profile PolyGeyser® Bead Filter operates concurrently as a clarifier and biofilter, total ammonia nitrogen (TAN) levels below 0.3, 0.5 and 1.0 mg-N/l can be expected at feed loading rates of 0.5, 1.0 and 1.5 pounds feed per cubic foot of EN bead media (8, 16 and 24 kg-feed m-3 day-1), respectively.