Endurance Configuration Instructions

The AST Endurance is designed for long lasting operation. The filter is trigger to backwash by the air pump. AST recommends owning a duplicate air pump or back up air system in the event of pump failure.

The air pump needs to be placed on location, and an air lines ran to the air inlet point on the filter. An air check valve should be installed to keep water reaching the air pump or the air pump can be located above the water level on a high shelf so that water cannot reach it. If water gets to the air pump, it can burn out the pump or cause a dangerous electrical situation.

The AST Endurance can be configured for automatic sludge removal. See the Endurance manual for details.

For Winter Preparation:

There are no annual maintenance requirements for the Endurance filters. If the unit is going be shutoff for more than a few days, the sludge basin should be thoroughly drained to prevent excessive thickening of the sludge. If hard freeze conditions are expected then the exposed trigger pipe must be drained or ice expansion can cause damage. To restart a unit, set the air input to the rotometer at the top of the scale to force a backwash every few minutes. This will move beads back to the filtration compartment. Then set the airflow back to achieve a 3 hour backwash interval ( 0.25 and 0.7 cubic foot per hour) which is generally ideal for koi pond applications.

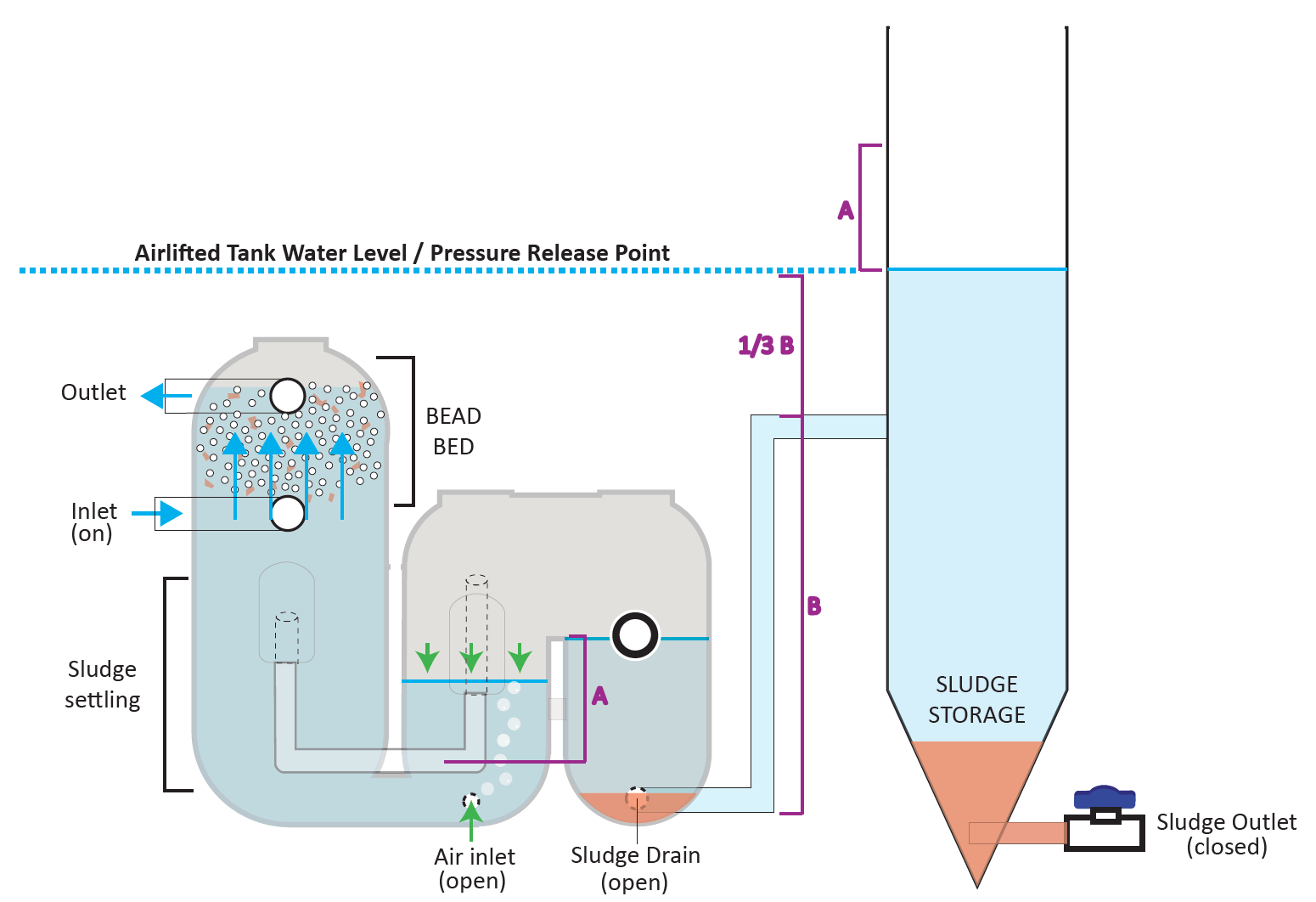

Airlifted Setup

Endurance Models can be configured to run on an airlifted plumbing setup, eliminating the need for a water pump. The U- bend pipe has air injected into the first tube nearest the filter. As these bubble rise, they lift the water up through the tube and back into the tank. For an airlifted setup to work, the water level has to be at least 12 inches above the top of the filter. See the Endurance Manual for more details.

Endurance Water Exchange

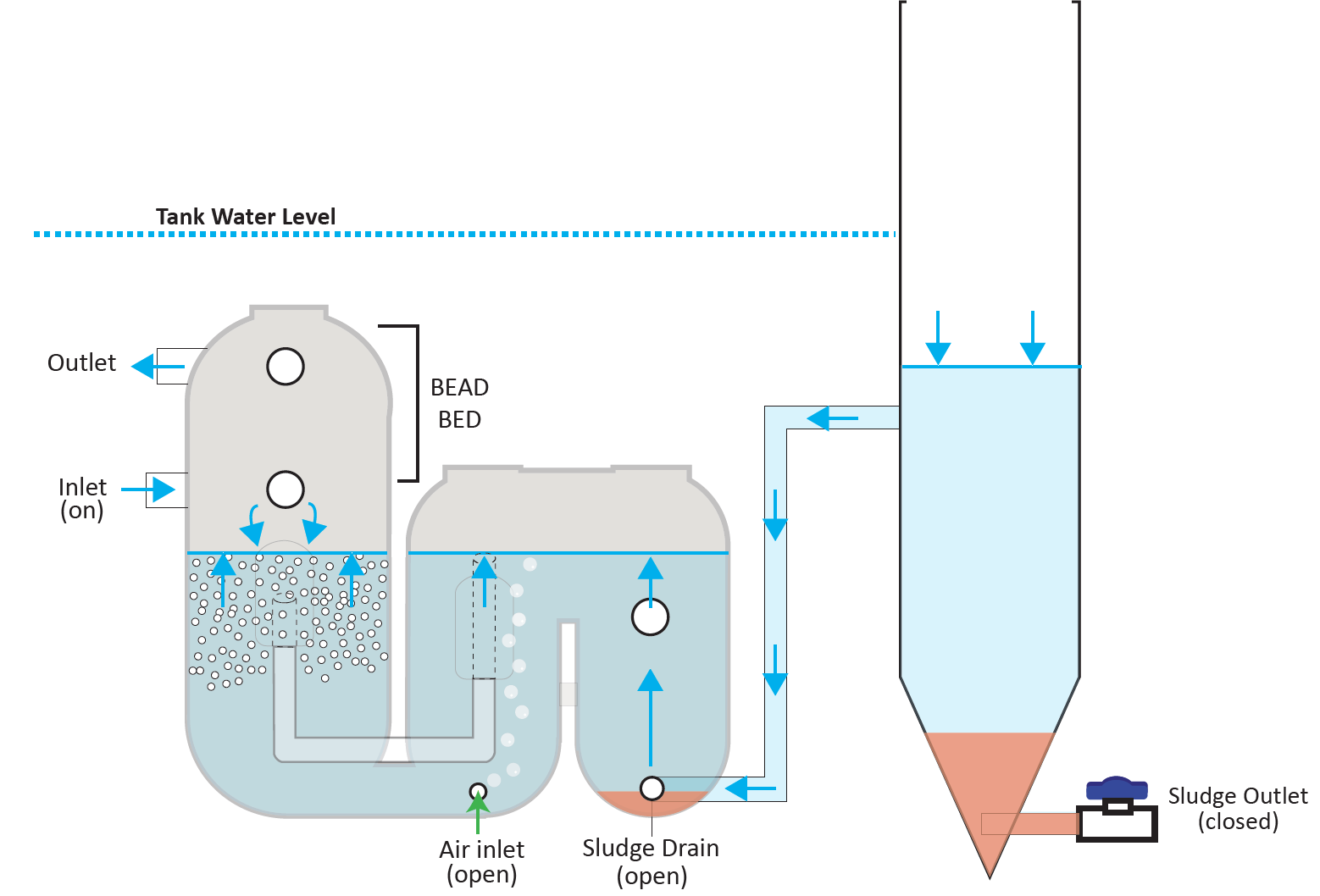

External Reservoir setup

The Endurance Polygeyser® filter (shown on the left in the diagram) is connected to an external reservoir such as a tank or

sump. This reservoir is for sludge settling and is setup in such a way that clarified water can be drawn back through the discharge pipe, maintaining a consistent water level within the culture system.

Sludge is purged to settle

At the end of the backwash, the sludge from the filter is forced through the connecting pipe into the external reservoir. There, the sludge settles to the bottom and clarified water inhabits the upper level of the reservoir. This clarified water is the exchange water that is pulled into the filter during the exchange sequence.

Clarified Waters are drawn back into the culture system

As the tank refills after backwash, the clarified waters in the top of the reservoir are drawn back into the system.

It is important to drain the external reservoir periodically as a buildup of nitrites and nitrates will occur as the wastes breakdown. The advantage of this system is that it maintains a consistent water level in the culture system even as solids are being purged from the system.

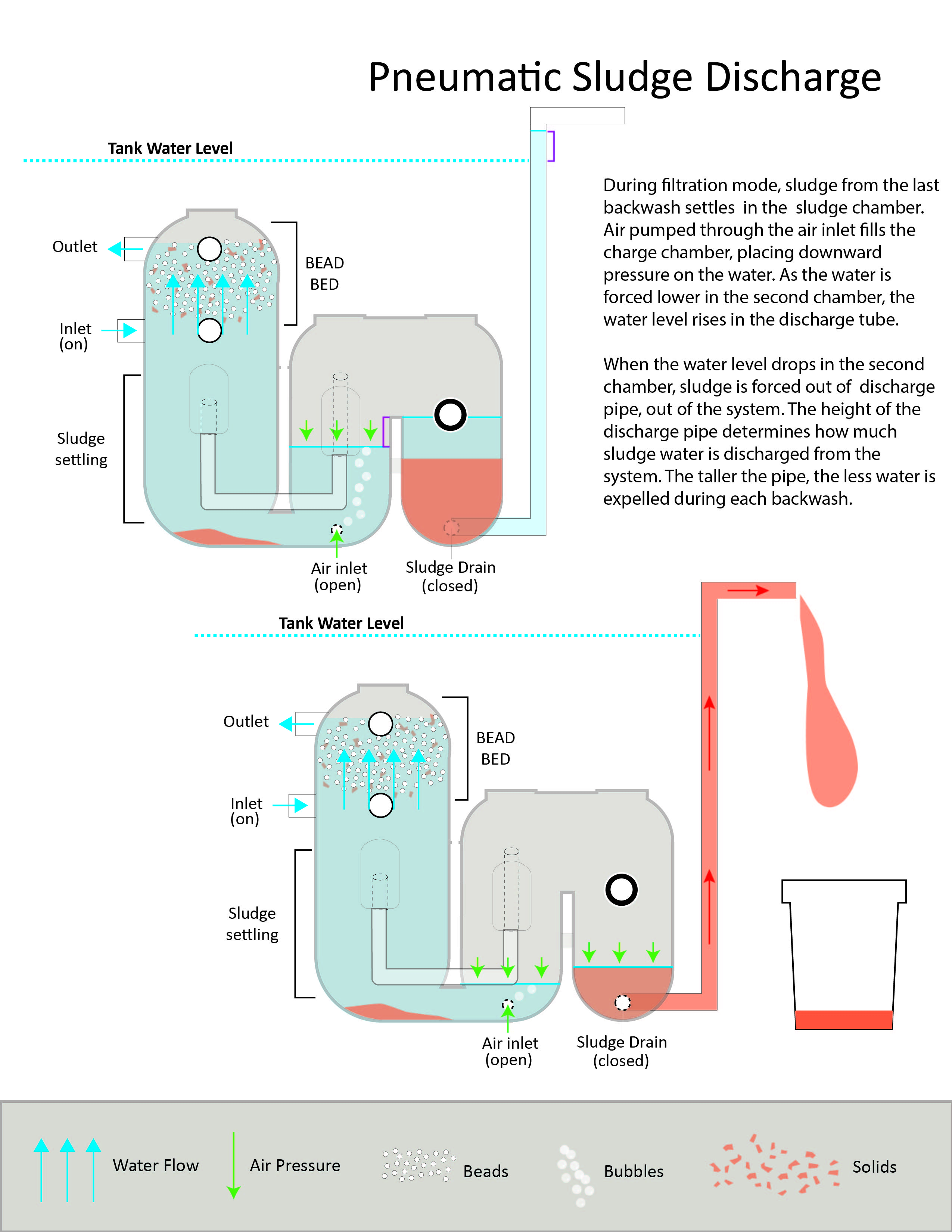

Pneumatic Sludge Discharge

This is a simple setup that provides advantages in setups requiring high water quality with as little ammonia, nitrite, and nitrate as possible. The waste materials are preemptively purged out, limiting their decomposition within the system. The Endurance can be set to backwash regularly as frequently as six times a day, each time purging a small bit of the accumulated sludge

Setting up a high discharge pipe, ideally adjustable in height, lets the user control the waste being purged out of the system. The water has to be topped off regularly, as this method does discharge a portion of your system volume. The higher the discharge pipe, the less volume will be pushed out of the system.