Bubble Bead Operation and Backwash

The Bubble Bead® Filter is effective at removing unwanted solids, yet gentle enough to maintain a healthy bio-film. Please refer to the normal operation and backwashing diagrams below.

There are 9 models available with from 1/4 – 10 ft3 (0.007 – 0.283 m3) of bead media capacity with flow rates ranging from 10-150 gpm (0.00063 – 0.0095 m3/sec).

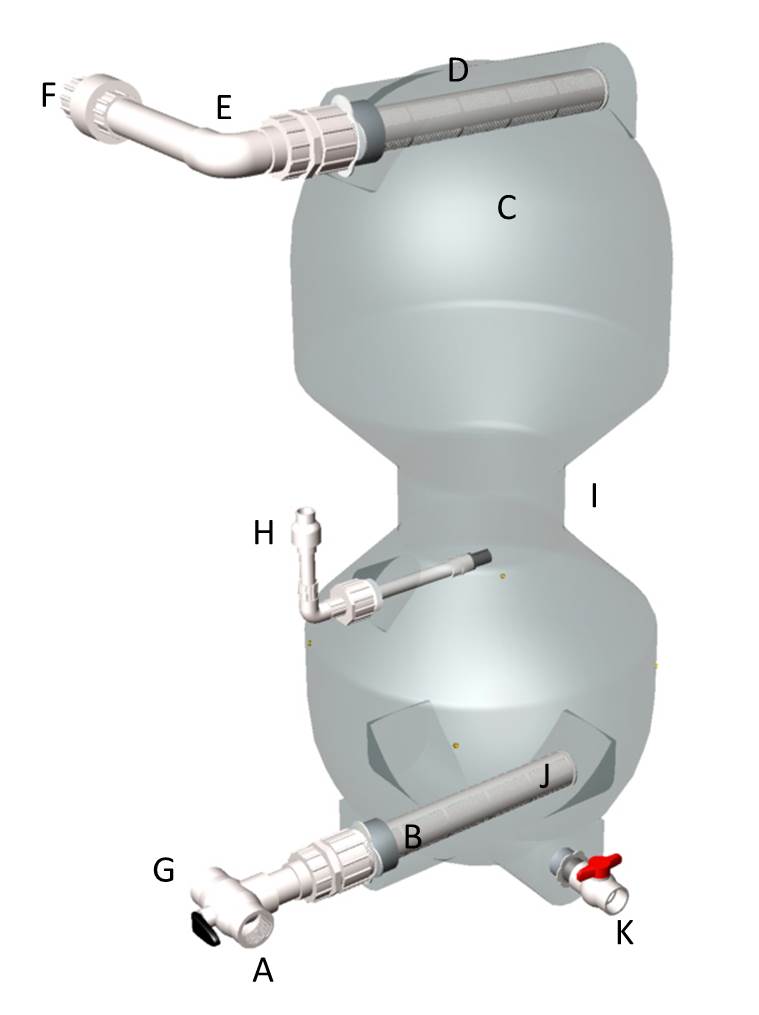

NORMAL OPERATION:

- Water is pumped through the Filter Inlet via a 3-way Valve positioned to (A) and the Diffuser (B).

- Water passes upwards through Bead Bed (C) for bioclarification and exits through Screen (D).

- Filtered water is returned through Effluent Line (E) and a Check Valve (F) to the aquatic system.

BACKWASHING:

- The pump (not shown) is turned off and the 3-way Valve at the Inlet is turned to the Sludge Drain Position (G).

- Backwashing is accomplished by completely draining the water from the filter.

- As water drains from the filter, the check Valve (F) on the Effluent Line closes and air is sucked into the Air Inlet Check Valve (H).

- Agitation of the beads is accomplished as air rises up through the Washing Throat (I) and beads and water drop down into the Expansion Chamber (J).

- As the beads enter the Expansion Chamber (J), they initially sink with momentum, and then float upwards as the water velocity decreases and buoyancy takes hold. As this occurs, water is sweeping past the beads which serves to carry away the solids freed from the bead media out of the filter.

- Once the filter unit has drained completely, the 3-way Valve is returned to position (A) and the Pump (not shown) is turned back on.

- An unscreened Emergency Drain (K) is provided at the bottom of the filter unit.

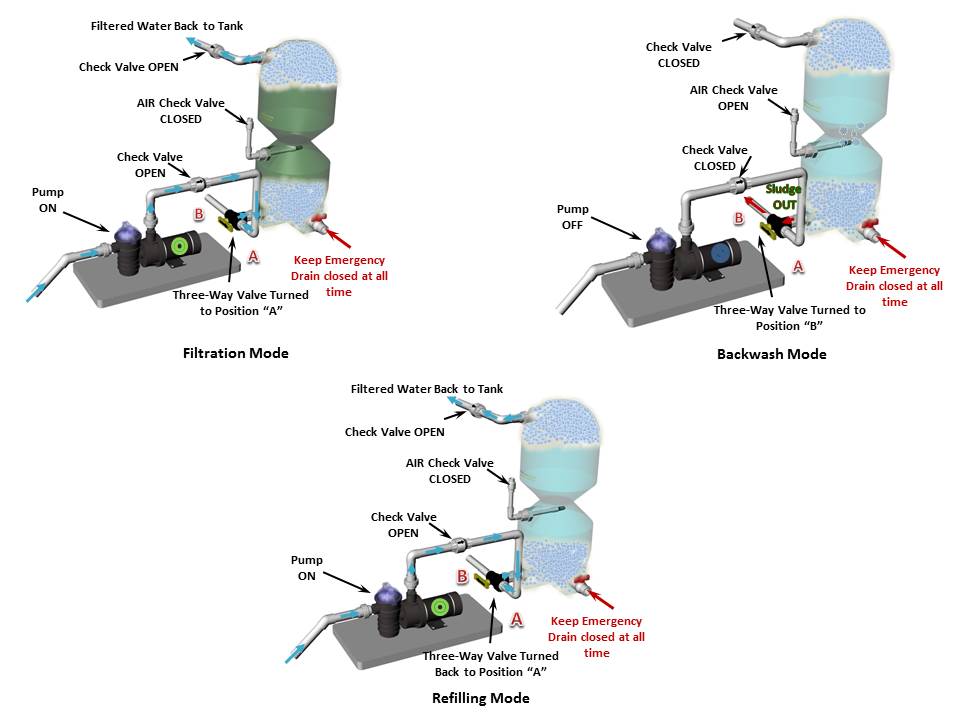

BACKWASH OPERATION:

Backwash operation includes three primary modes (diagram below): filtration, backwash, and refilling. Backwashing is accomplished by completely draining all fluid from the unit. This causes the bead bed to collapse, and individual beads to be vigorously scrubbed by cavitation and bubbles as they are sucked downward through the washing throat. The backwashing process removes solids captured by the bead bed, but retains the beads with their delicate films of nitrifying bacteria.