FIT System Operation & Backwash

These exceptional filters backwash automatically, several times a day. The user does not need to open or close any valves during the backwash sequence. The filter does not require an electric timer. The backwash cycle is regulated by the air that is injected into the charge chamber. The filters clean and recycle the dirty water produced in backwashing every two to three hours. Sludge is only removed once or twice a week.

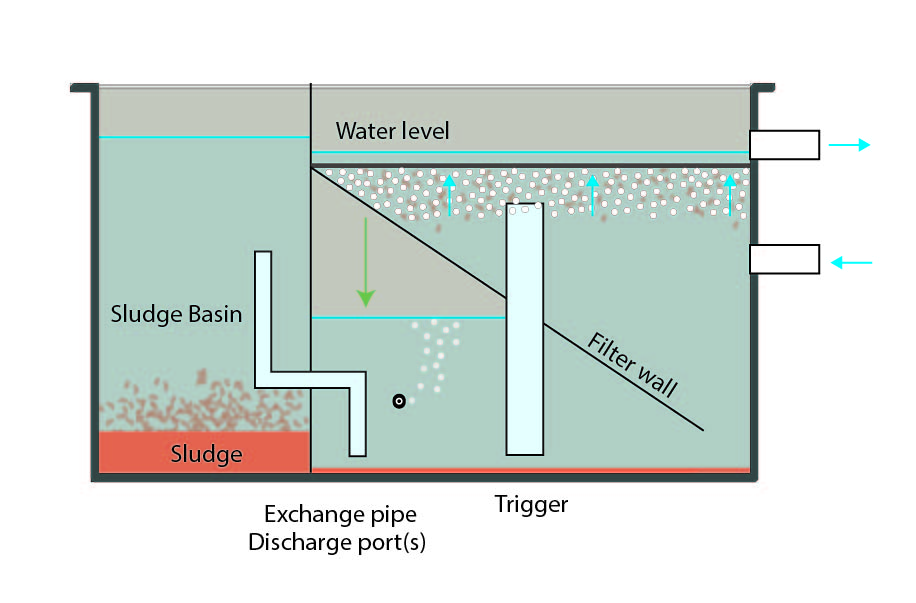

Before Backwash

The water moves from the inlet up through the bead bed. The bead bed provides surface area for the water purifying bacteria and captures solids within the aquatic system. Solids are collected within the bead bed. Air is slowly injected into the charge chamber, gathering in the top of the charge chamber. As more air enters, this displaces the water in the charge chamber, replacing it with air. The rate of air injection controls the length of time between backwashing events. Sludge settles in the sludge basin from the last backwash cycle.

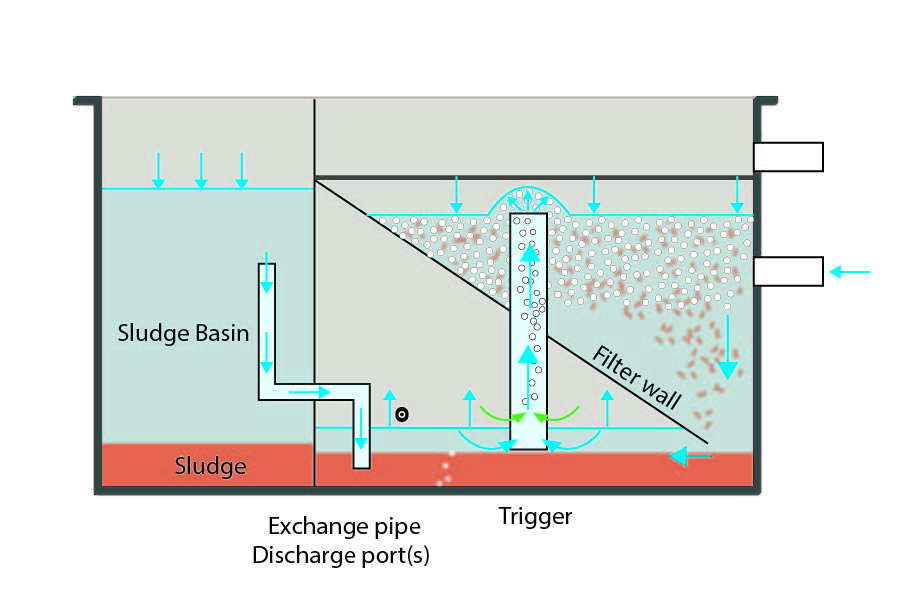

Backwash

Air has made its way through the trigger into the bead bed. The bubbles agitate the beads; knocking solids and biofilm off the beads. As the air pressure in the charge chamber drops, the dirty water from beneath the bead bed sweeps through the chute carrying the solids into the adjacent compartment. No water flows out of the filter during the short 3-5 second backwash event; instead the dirty backwash water is captured in the charge chamber and the sludge basin. The beads float in the drop zone where they continue to be scrubbed by the escaping bubbles.

After Backwash

Water continually fills the filtration chamber. At the same time, the air pump is continuing to push air into the charge chamber. Solids that have collected under the bead bed are swept up and out of the discharge ports and are deposited in the isolated sludge basin. The filtration chamber is refilled with the water from the inlet. The beads float back in place to reform the bead bed. As soon as the water rises to the outlet, normal filtration resumes.

Normal Filtration

The water moves from the inlet up through the bead bed. The bead bed provides surface area for the water purifying bacteria and captures solids within the aquatic system. Air is slowly injected into the charge chamber, gathering in the top of the filter. As more air enters, this places downward pressure on the water level. The water level drops trapping water in the settling zone, and solids from the last backwash settle into the sludge basin. The rate of air injection controls the length of time between backwashing events.

Periodically Drain Sludge

The filter will continue to filter and backwash itself several times a day. After the sludge has built up, the user can open the sludge valve to drain the concentrated sludge from the filter. The filter backwashing frequency is usually set for a few hours, resulting in the filter backwashing several times a day. Sludge accumulates in the sludge basin. Every few days, perhaps once a week, the sludge drain must be opened to let the sludge out. A natural fertilizer, the sludge can be mineralized and utilized in hydroponic grow beds or land applied where it will naturally degrade. This sludge will have a “rotten egg” smell that will dissipate with exposure to air.

Operation:

Keep the correct water level for optimum filter performance. The water level should run at the diameter of the return pipe. This is half of the pipe’s return height, leaving plenty of room for air to push the water along.

These Polygeyser® filters will backwash themselves so you do not need to manually initiate backwashes on a regular basis. You will need to adjust the air using your suflow air gauge, so that your unit regularly backwashes four to six times a day. If you notice your filter is not backwashing as vigorously as it has been previously, running the air on high will force the unit to backwash a few times to dislodge stubborn deposits. Be aware that the water will become temporarily cloudy from fine solids. Then reset the air gauge to the typical four to six backwashes a day and normal operation will take care of the rest.

Debris can collect on the filter water intake, affecting the filter’s ability to clean the water. Check the filter intake regularly to ensure nothing obstructs the water flowing into the filter. Inadequate flow means the filter will not backwash properly and ammonia will build up within the system.

Due to the current in the water, dead fish may not float to the top of the unit. Check your intakes within the filter and remove any dead promptly. Make sure your screens are large enough to keep the fish out of the plumbing so that they do not get trapped where you cannot see them. If fish are stuck to the water intake, flow through the filter is reduced, hindering a proper backwash cycle. This is a bad feedback loop that can be remedied by quick removal of dead fish and a water change if needed. If dead fish are not removed, water quality will worsen; killing more fish and blocking the filter from functioning at all.

FIT backwash diagram and written description

When Draining Your Filter Water

These units are different from many filters on the market, and special care needs to be taken when draining these filters due to the unique auto-backwashing mechanisms.

- Do not drain the tank completely unless the inlet valve is closed. Beads will escape the filter if the valve is open.

- When draining the filter while the inlet valve is open, do not drain below the inlet or beads will escape.

Setting the Sludge Removal

If your filter is utilizing the auto-purge features, there different methodologies for setting the amount of sludge to be removed. You can adjust air flow remove more or less sludge.

For mineralization, consider letting more sludge pile up within the sludge chamber for digestion. This can help increase available nitrates for plant culture. Test the water quality to ensure the water remains suitable for the fish. More frequent water changes may be needed, or more frequent backwashes to remove excess solids. Running at a lower air pressure will keep the system from purging larger solids from the system.

For fish culture exclusively, purge sludge preemptively to prevent declines in water quality. Set your unit to remove larger amounts to lower the amount of waste breaking down in the system. Adjusting for more powerful air flow will result in a stronger current that will lift more sludge and waste out of the filter. This filter will also backwash more frequently when being operated in this manner.