Meat/Poultry Processing

Meat processing (pork, beef, poultry, game, etc.) plants generate large volumes of wastewater with high levels of organic matter, BOD/COD, TSS, Ammonia/TKN, fats, oils, and grease (FOG)*. This wastewater can pose a number of environmental and public health problems if it is not properly treated. To address these wastewater issues, meat processors install and operate wastewater treatment systems that are designed to remove the pollutants from their wastewater.

Challenges:

- The high volume of wastewater generated: pork, beef, poultry, game, and other meat processing plants generate large volumes of wastewater, which can be difficult and costly to treat.

- The variability of the wastewater stream: The wastewater stream from meat processing plants can vary in composition and strength, making it difficult to design and operate a wastewater treatment system that is effective at all times.

- The cost of wastewater treatment: Wastewater treatment can be a significant cost for meat processors. This is especially true for small and medium-sized businesses.

*AST Filters are not sensitive to moderate FOG loading and have been used in the treatment process in conjunction with Dissolved Air Flotation (DAF) systems to provide the biological treatment the DAF lacks.

Introducing a pretreatment system and operating it properly will reduce surcharges, penalties, and fees, providing more control over wastewater treatment costs.

Despite these challenges, there are a number of effective wastewater treatment technologies that can be used.

AST provides efficient, cost-effective, onsite wastewater treatment system solutions.

Our customers tell us that they typically consider multiple competing solutions. Here is a snapshot comparison of two technologies used for Biological Treatment.

Case Study: Poultry Processing Facility, Gainesville, Georgia

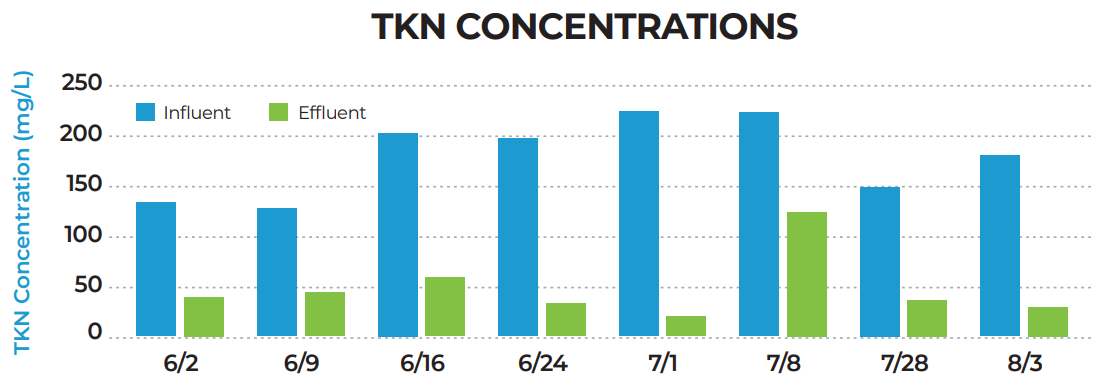

For convenience here is a recap of a recent Pilot project in Georgia for a major Poultry producer. The local Municipality ordered the plant to reduce levels of BOD and TKN in their discharged wastewater to compliance levels or scale back production.

THE RESULTS:

The AST treatment system averaged 90% reduction in BOD and 76% reduction in TKN. The study proved the technology was not only capable of bringing the facility back in compliance but, on average, reduce the concentrations below surcharge limits. The poultry processing facility won municipal approval for the technology.

Let's Discuss Your Project

From a simple filter to a complete custom system, our engineers can help you find the perfect filtration system for your needs. Get in touch today!