Recirculating PolyGeyser (RCPG)

Simultaneous Biological and Mechanical Filtration

The Recirculating PolyGeyser (RCPG) is designed to provide both biological and mechanical filtration simultaneously. Geared to tackle wide range of BOD, TSS and ammonia loadings, the RCPG can treat the toughest waste streams and meeting the strictest discharge limits.

BENEFITS OF AST’S Recirculating PolyGeyser (RCPG)

- Eliminate Surcharges

- Meet Stricter Discharge Limits

- Reduce Water/ Power Usage

- ROI within 1-5 years

- Superior results to surface aeration

RCPG Project Photos

How It Works

Treatment Operation

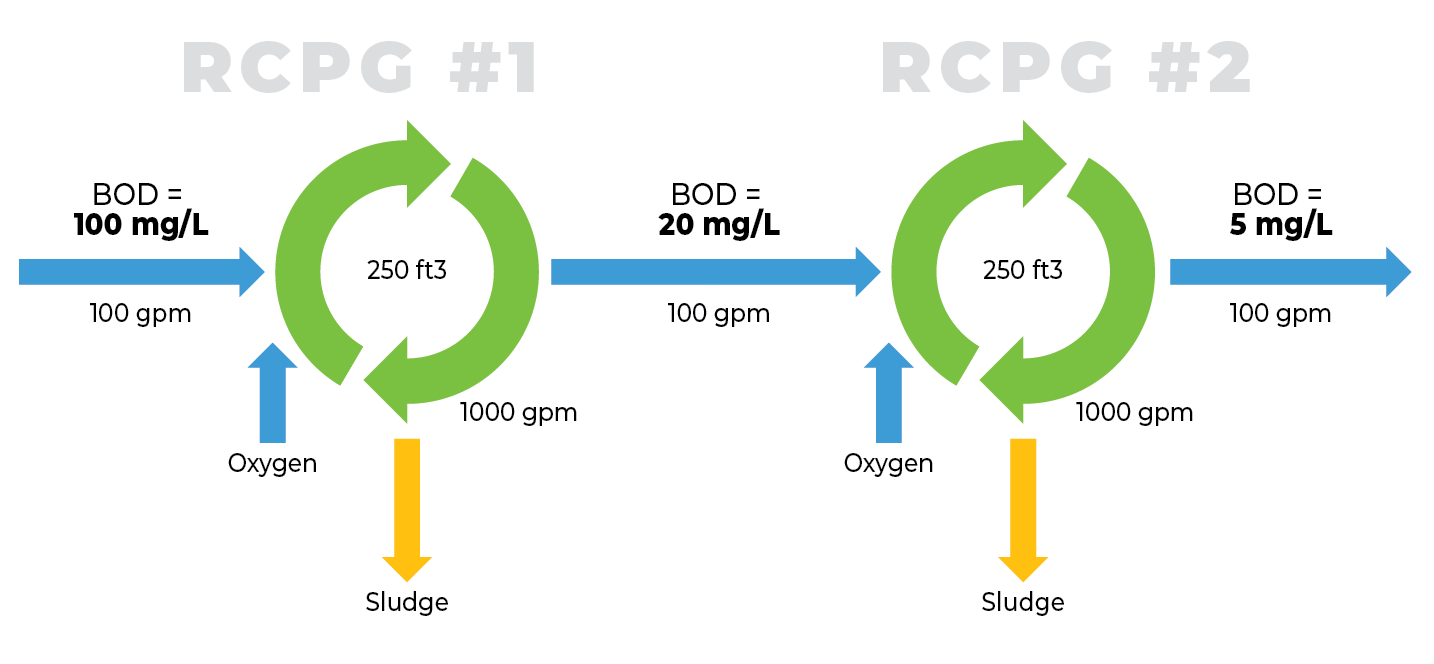

The Recirculating PolyGeyser (RCPG) is an aerobic treatment process that uses a low-density polyethylene bead media to remove suspended solids (TSS) and soluble organic contaminants (BOD, Ammonia). During the normal operation the floating bead media forms a static, packed bed at the top of the unit. Mechanically, as water courses up through the media bed, solids are captured. Biologically, a bacterial film grows on the surface of the media consuming soluble organics. The units include an airlifted recirculation loop. The recirculation loop operates at a higher flow rate than raw water is fed to the system. As a result, incoming water passes multiple times through the media before discharging. The ratio of the feed rate to the recirculation rate can be adjusted based on the waste strength and discharge criteria of a particular application.

Automatic Air-driven Backflush

The RCPG incorporates an automatic, air-driven backwash. Air from an external compressor feed into a charge chamber contained in the unit. Air accumulates in the unit until it reaches the trigger volume at which point air is rapidly released into the bead bed above. The air expands and mixes the media releasing captured solids and overgrow biomass. As the air releases, the solids laden water fills the void created in the charge chamber. Over the course of the next air fill cycle solids settle to the bottom of the unit forming a concentrated sludge. The backflush event lasts 10-15 seconds and does not interrupt flow to the unit.

Auto-pneumatic Sludge Removal

The RCPG automatically discharges captured sludge. The backflush air being fed to the unit This occurs automatically shortly before a backwashing event.

Modular Approach

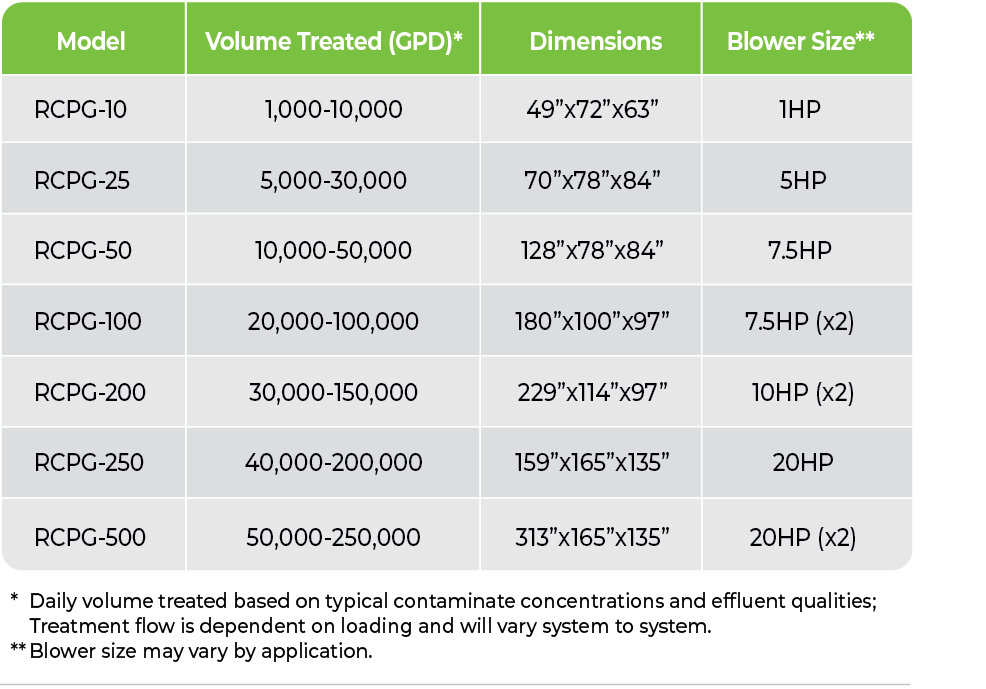

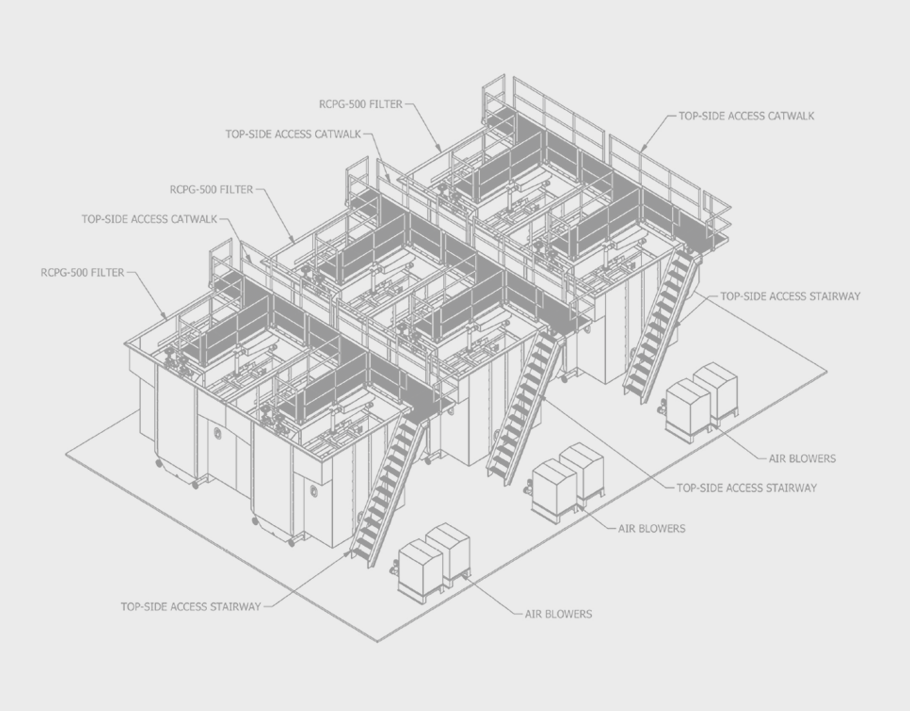

The Recirculating PolyGeyser (RCPG) employs a modular design approach. Multiple units can easily be installed to operate in tandem. The result is higher BOD conversions rates in an easily expandable system For growing business, this means your system treatment capacities can easily be expanded to meet increasing treatment demand.

Daily BOD conversion rates in the RCPG are concentration dependent. The higher the effluent concentration discharging the from the unit, the higher the daily BOD conversion rate. For many BOD treatment applications, AST takes advantage of this by running multiple units in series. This approach increase the overall treatment rates thereby reducing the overall size and cost of the system.

Competitive Advantage

The Recirculating PolyGeyser (RCPG) is unique in that it accomplishes both biological and mechanical filtration in a single step. Biological treatment processes generally generate solids. Treatment processes like moving bed bioreactors (MBBRs) and extended aeration offer no method to control solids generated by the treatment. As a result, a downstream solids capturing process is generally needed for a full treatment solution. The RCPG captures and removes solids generated through biological treatment eliminating the need for a secondary solids removal step. The result is a simpler, lower cost solution with a smaller footprint.

AST Filters can provide solutions for a variety of applications. What sets us apart from other wastewater treatment companies is our process consolidation, lower energy requirement and our excellent customer service. AST has found our treatment process can be 20%-40% more cost effective than other solutions on the market and we strive to provide a Return on Investment within 1-5 years. Stop overpaying for wastewater systems and get back to focusing on growing your business.

Let's Discuss Your Project

From a simple filter to a complete custom system, our engineers can help you find the perfect filtration system for your needs. Get in touch today!