High Profile PolyGeyser (HPPG)

Aggressive solids control and biological treatment

The High Profile PolyGeyser (HPPG) is capable of handling high solids concentrations (TSS) while still removing fine particulate. Simultaneously the unit function biological filter and can be configured for ammonia, soluble BOD and denitrification treatments.

BENEFITS OF AST’S High Profile PolyGeyser (HPPG):

- Ensure Environmental Compliance

- Eliminate Surcharges

- Control nutrient concentrations

- Fast ROI

How It Works

Treatment Operation

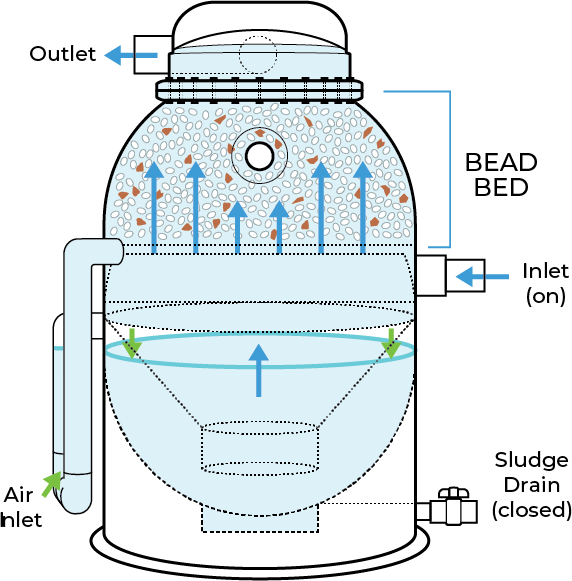

The High Profile PolyGeyser (HPPG) contain a floating bead media that forms a packed bed at the top of the unit. Water flows into the side of the unit, up through the packed bead bed and discharges from the top of the unit. The packed bead bed captures suspended solids (TSS) as the water courses up through the unit. Treated water discharges from the top of the unit.

While the units are excellent for solids capture, they also function as biological filters. A thin film of bacteria grows on the surface of the media. The bacteria consume dissolved organic contaminants while simultaneously removing solids. This allows the units to reduce BOD and ammonia concentrations. They can also be configured to lower nitrogen (TN) concentrations via biological denitrification.

Backflush and Sludge Storage

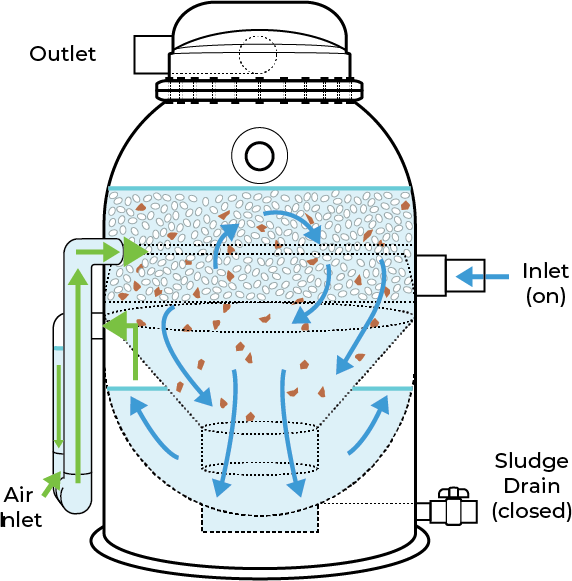

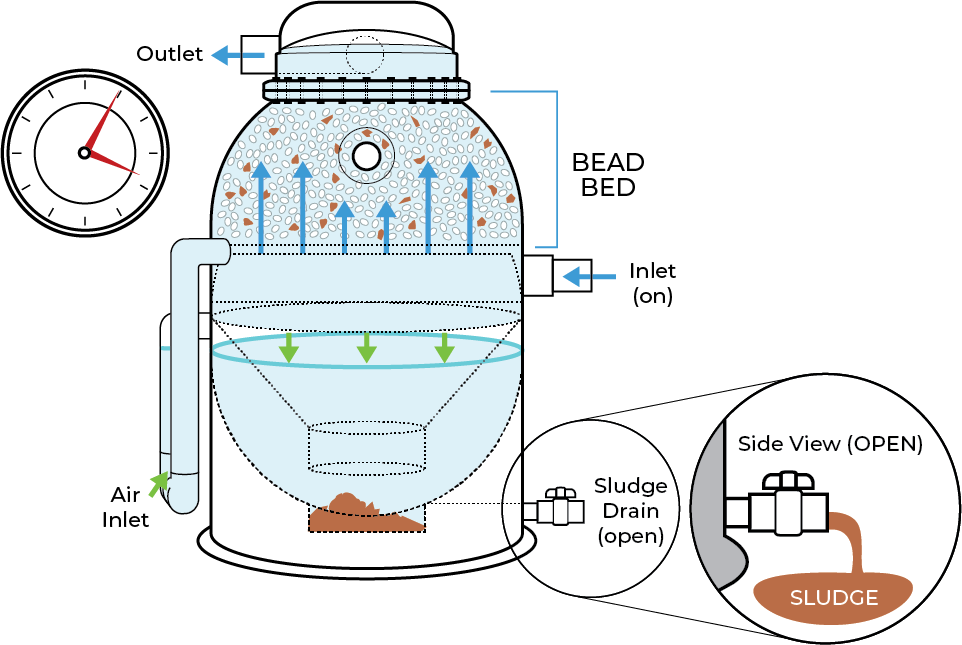

The High Profile PolyGeyser (HPPG) operates using a rapid automatic air-driven backflush. The backflush frequency is controlled by the rate air is inputted into an internal charge chamber. Backflush air is typically supplied by a small compressor. Actual backflush events occur in a matter of seconds and do not interrupt input flow to the unit.

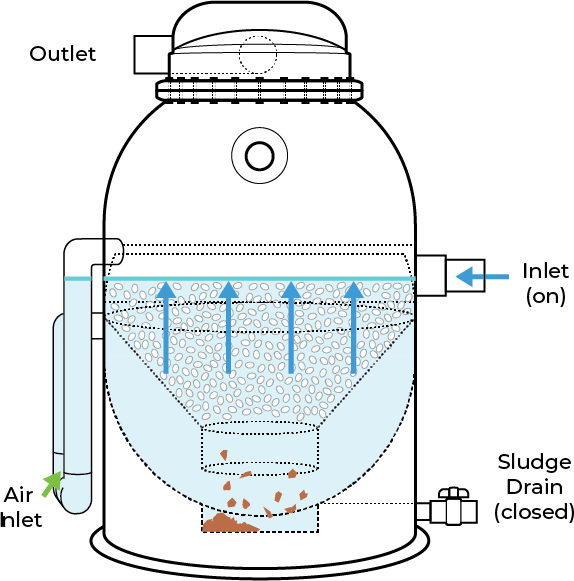

After backflushing, captured solids settle to the bottom of the unit forming a concentrated sludge. Incoming water fills the unit back up seamlessly resuming normal operation without downtime.

The Advantage of Air

The automatic, air-driven backflush makes these very versatile offering a slew of operational advantages and benefits. The speed at the which the backflush is complete allows the units to be backflushed as frequently as the application calls for with no added cost or labor to the operator. As a result, the units can easily be tuned to treat a wide range of TSS concentrations.

The air driven backwash concentrates captured solids minimizing the volume of waste produced. This means less effort and lower disposal costs in comparison to traditional treatment approaches.

HPPG FEATURES

- Low pressure operation

- Automatic operation

- No moving parts/electronic controls

- Minimal maintenance/oversite

- Compact footprint

- Simple integration

Let's Discuss Your Project

From a simple filter to a complete custom system, our engineers can help you find the perfect filtration system for your needs. Get in touch today!