Case Study

Dairy Processing Plant

Texas

Wastewater produced at a dairy processing facility in Tyler, TX contained high concentrations of BOD, TSS and FOG. An existing dissolved air floatation (DAF) treatment system at the facility was able to effectively reduce TSS and FOG concentrations of the wastewater. However, due to the high sugar content of the waste stream, the BOD concentrations remained high. As a result the facility continued to pay the local municipality surcharges for high strength wastewater.

Problem:

AST was contacted by the dairy processing facility with the hope that its bead filter technology could provide a cost-effective solution to eliminate BOD surcharges and ensure compliance with the local municipality.

Solution:

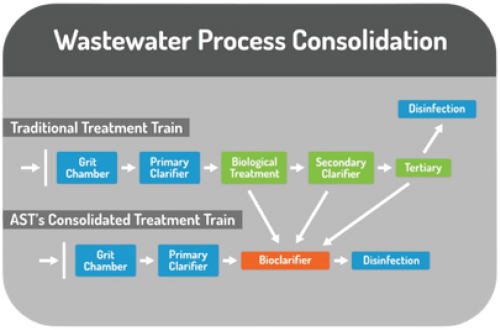

AST integrated its 500 ft3 Recirculating PolyGeyser (RCPG-500) treatment system and effectively eliminated all BOD surcharges for the facility. Additionally, the RCPG-500s dual functionality as both a biological and mechanical filter eliminated the need for any downstream solids removal processes.

Results:

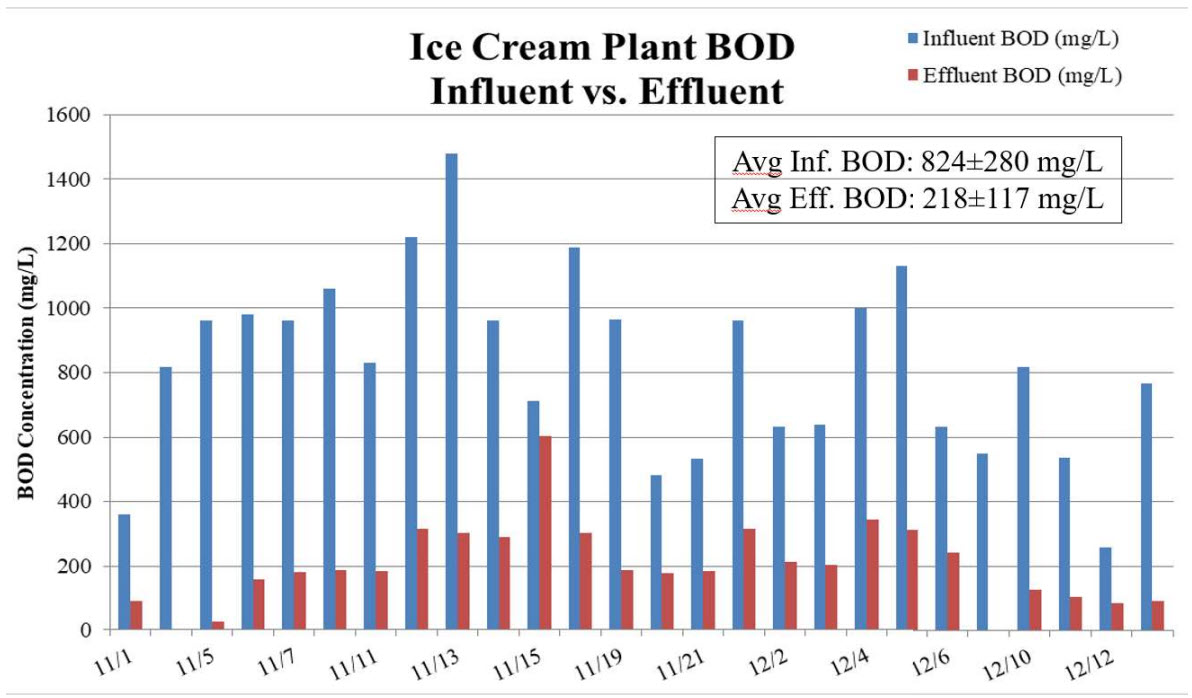

AST’s RCPG-500 was able to reliably reduce the BOD concentrations below 250 mg/l eliminating the facilities long withstanding municipal surcharges. (the graph below shows data collected from the facility)

Client Testimonial:

“AST has eliminated our surcharges and allowed us to focus on producing our product instead of focusing on wastewater compliance. For us it was a simple solution with an ROI that made financial sense.”

– Plant Manager

INNOVATION • SIMPLICITY • MULTI-FUNCTION

If you have questions about AST’s filtration systems or would like to learn how we can help with your filtration needs, please call us for a FREE CONSULTATION – 1 (504) 837-5575