Case Study: Brewery Wastewater, Littleton, Colorado

The Problem:

The process of brewing beer results in a waste high in BOD/COD & TSS. Municipalities can become overwhelmed with the amount BOD/COD & TSS coming in, which results in a surcharge to breweries that discharge their waste above a set threshold.

The Solution:

AST designed a compact wastewater solution that combines aerobicbiological treatment with solids capturing to efficiently target the BOD/COD & TSS found in brewery waste,

and even reduces water loss up to 99% compared to similar technologies.

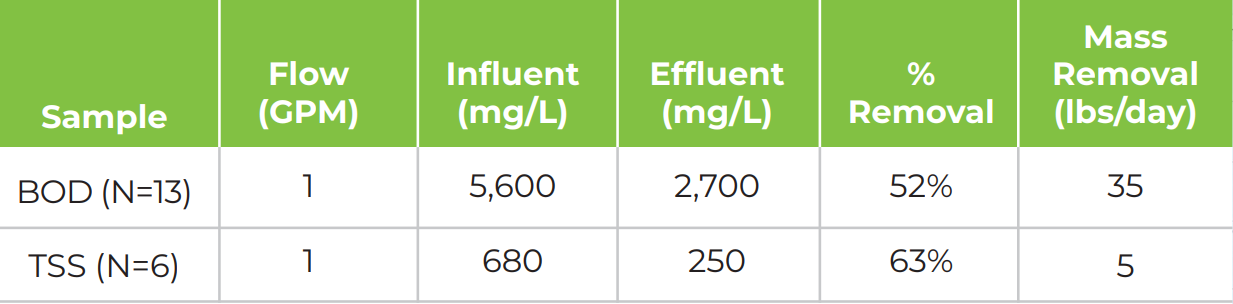

The Results:

After Implementing AST’s RCPG 10 Pilot recommendation, this brewery met the required discharge criteria for BOD/COD & TSS, reducing municipal surcharges.

RCPG 10 FILTER

System Benefits:

• High Efficiency

• Low O&M

• Automated Non Mechanical Backwash

• Simultaneous Mechanical and Biological Filtration

System Applications:

• Municipal and Industrial Wastewater

• High Strength Wastewater

• Pristine Polishing

INNOVATION • SIMPLICITY • MULTI-FUNCTION

If you have questions about AST’s filtration systems or would like to learn how we can help with your filtration needs, please call us for a FREE CONSULTATION – 1 (504) 837-5575