Moving Bed Biofilm Reactor (MBBR) vs. Bead Filters for Wastewater Treatment

The MBBR (Moving Bed Biofilm Reactor) and the Floating Bead Filter are both plastic floating media biofilters that can eliminate soluble Biological Oxygen Demand (BOD) from the system. These filters are widely used in aerobic treatment and can be redesigned to function in an anaerobic format for denitrification. However, they have different advantages and disadvantages.

MBBR systems are fixed film bioreactors that use a moving bed of support material, typically plastic biocarriers, to grow microorganisms. In aerobic treatment, the biocarriers are constantly mixed by air injection, which keeps the water aerated and provides abrasion to remove excess biofilm. The discharge from the MBBR is screened to contain the biocarriers. Biocarriers tend to be 10-20 mm large to avoid screen clogging. Originally developed for aquaculture applications, they are capable of good rates of conversion of dissolved organics (BOD) and ammonia. They have also been successfully applied to municipal and industrial waters. The MBBR has no specific solids removal capacity.

Floating Bead Filters are granular filters that use a static bed low-density plastic (specific gravity <0.92) media bed to filter up flowing water. The media (typically 2-3 mm) is retained by an overlying screen which gives them the ability to capture solids. Floating bead filters that are designed to function as a biofilter inherently capture suspended solids and are referred to as bio clarifiers since they can perform a dual function. Backflushing scours excessive bacteria off the outer layers of the biofilm, creating ideal conditions for diffusion of critical nutrients to nitrifying populations that normally reside close to the biocarrier surface. Backwashing breaks up the media preventing excessive head loss and improving the biofiltration rates.

AST has developed different Floating Bead Filter models specifically for Industrial and Municipal scale Wastewater operation.

The High Profile PolyGeyser (HPPG) employs pneumatic backwashing, which simplifies operations and moderates’ abrasion during backwashing. The HPPG is a single-pass unit designed primarily as a clarifier. It can be linked to an external aerated tank to become effective in a bio clarifier mode.

The Recirculating PolyGeyser (RCPG) links an internal head tank with an airlift to facilitate the treatment of organic or ammonia-rich waste waters that require very high oxygen demand. The water is rapidly re-aerated and passed through the bed multiple times to achieve the treatment objectives.

The RCPG can augment, complement, or replace an MBBR and its associated clarifiers. The HPPG is normally used to support an MBBR, replacing one or both of the associated MBBR clarifiers.

Both MBBR and the RCPG types of filters can operate with highly equivalent results as biofilters with the Bead Filter also providing solids capture, acting as a bioclarifier.

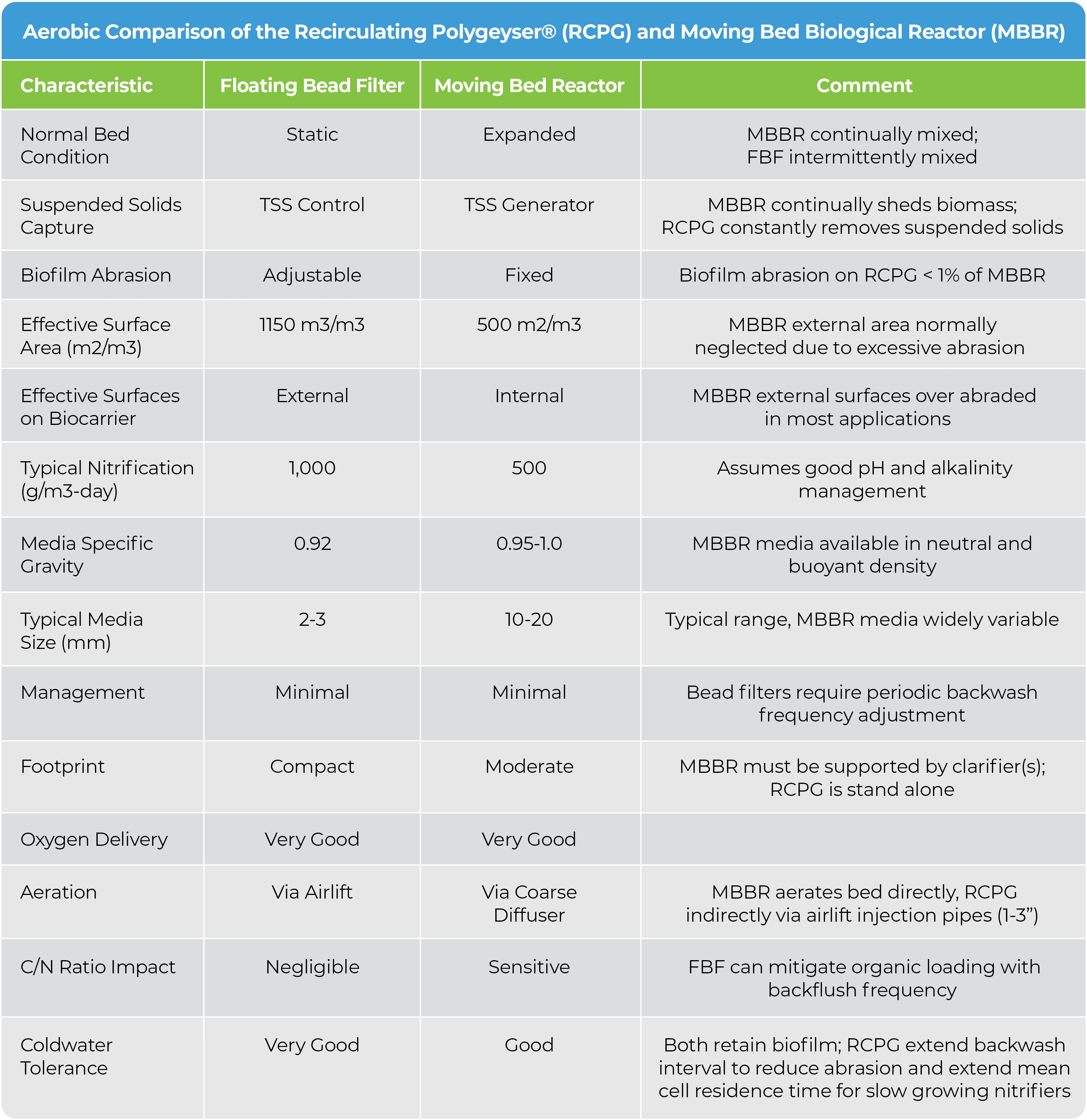

Comparisons with MBBR below all refer to the Multi pass Recirculating Floating bead filter (RCPG)

MBBR (Moving Bed Biofilm Reactor):

- Filtration Mechanism: MBBR systems have no solids removal mechanism and generate solids that must be removed by a clarifier. They use plastic media with a moderate specific surface area to support the growth of biofilm, which helps break down dissolved organic matter in wastewater.

- Treatment Efficiency: MBBR systems are efficient in removing both soluble organic pollutants and ammonia from wastewater.

- Biological Treatment: A MBBR is a fixed-film bioreactor. In the normal aerated configuration, they can be used to oxidize organics or nitrify for a variety of applications. When configured with mechanical mixing, the MBBR can be used for denitrification.

- Footprint: MBBR systems are compact and have similar space requirements compared to floating bead filters for similar treatment capacities. In most circumstances solids removal requires two extra steps, pre and post MBBR, in the treatment train making full solution generally have a larger footprint.

- Maintenance: MBBR systems require little maintenance. Periodic inspection of outlet screens may be required in some applications. Routine maintenance of blowers is required. Most MBBR reactors operate without internal moving parts. Periodic cleaning of injectors may be required in hard waters. Replacement of media every decade may be required for some biocarrier designs.

Floating Bead Filters:

- Filtration Mechanism: Floating Bead filters operate through biological and physical filtration. The use of small plastic beads as a static filter media allows them to remove suspended solids and creates a large surface area to support the growth of biofilm. The bacteria in the biofilm break down dissolved organic matter in wastewater. The biofilm can also be effective at nitrification. The static bead bed simultaneously removes suspended solids, dissolved organics, and ammonia from wastewater with periodic backwashing.

- Treatment Efficiency: Floating bead filters are effective at removing organic pollutants, ammonia, and suspended solids. AST bead filters provide high-efficiency biological treatment and solids removal.

- Biological Treatment: Floating bead filters must be equipped with a recirculating aeration loop to be effective bioclarifiers. Recirculating models are very effective at biofiltration even when used as mechanical filters. The backflush frequency can be adjusted to optimize the biological processes. They are adaptable to a very wide range of concentrations and do not require pre- or post-clarification., so the overall operation is very compact compared to an MBBR. They are excellent at reducing organic contaminants and nitrogen compounds (like ammonia) through nitrification.

- Footprint: Bead filters require similar space compared to MBBR systems for equivalent they biofiltration step, but typically requires a three-step process. treatment capacity. AST bead filters offer the ability to consolidate the footprint of the overall treatment train with its solid’s removal capabilities.

- Maintenance: The Floating bead filter requires little maintenance as there are no internal moving parts. Weekly inspection of beads through the viewing window and adjustment of the backwash air delivery rate as required is typically recommended for bio clarification. The AST floating bead filter features automatic sludge removal.

- If you require efficient biological treatment, for the removal of organic matter and nitrogen compounds, MBBR and AST Bead Filters are effective choices.

- AST bead filters are excellent choices for their compact footprint and high treatment efficiency where stringent effluent quality standards or high influent concentrations must be dealt with . In situations where space is limited AST bead filters may be preferable due to their multi-process functionality.

- If you have an installed MBBR a floating bead filter may be used in a complementary manner to enhance MBBR performance by polishing the effluent for BOD, ammonia, and solids or as a pretreatment to reduce organic loading. The Bead Filter can augment, complement or replace the MBBR.

Let's Discuss Your Project

From a simple filter to a complete custom system, our engineers can help you find the perfect filtration system for your needs. Get in touch today!